Three Ways to Save Time and Money with Trimble Technology

Construction projects are notorious for their complex nature, tight timelines, and budgetary constraints. In an industry where every minute and penny counts, finding innovative ways to optimize efficiency and cut costs is essential. That’s where having the right technology solutions comes into play. Adopting effective construction technologies can increase productivity up to 40%. In a market brimming with options, Trimble stands out as an industry leader, offering a comprehensive suite of solutions that cater to the unique needs of the industry. In this article, we will delve into the key features of Trimble construction technology and why it is the top choice for those seeking to maximize productivity and optimize costs.

1. Enhanced Precision and Accuracy

1. Enhanced Precision and Accuracy

Accurate surveying is fundamental to the success of any construction project. Trimble offers cutting-edge positioning technology that leverages high-precision GPS and GNSS technology such as GNSS Antennas, GNSS Correction Sources, GNSS Radios, and more. These technologies offer centimeter-level accuracy, allowing for accurate mapping, surveying, and layout of job sites. By integrating these systems into heavy machinery and surveying tools, construction teams can effectively follow design plans, contours, and grade specifications, reducing costly errors and rework. Trimble also enables advanced measurement and 3D modeling capabilities, revolutionizing the way construction projects are planned and executed. The laser scanning and imaging solutions allow for the accurate capture of as-built conditions and the creation of detailed 3D models. By eliminating the need for manual or outsourced surveying methods, Trimble systems can effectively streamline the process, resulting in substantial time and labor cost savings.

2. Efficient Machine Control:

2. Efficient Machine Control:

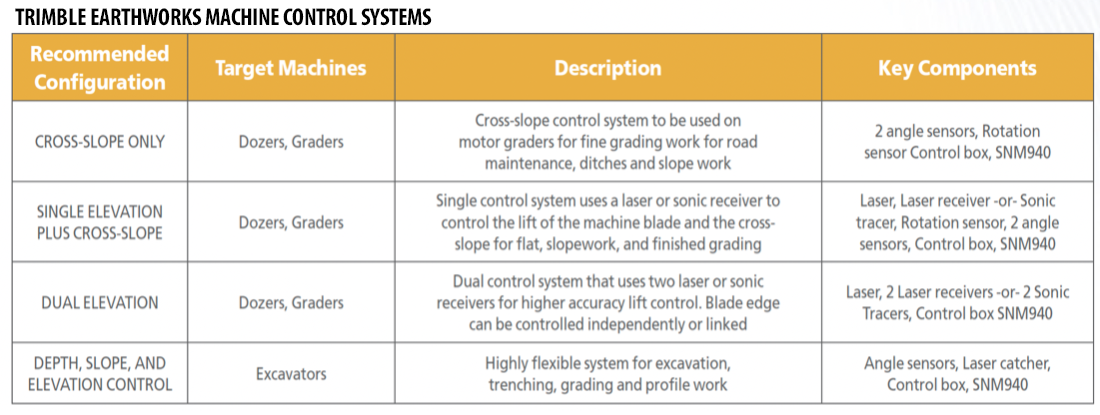

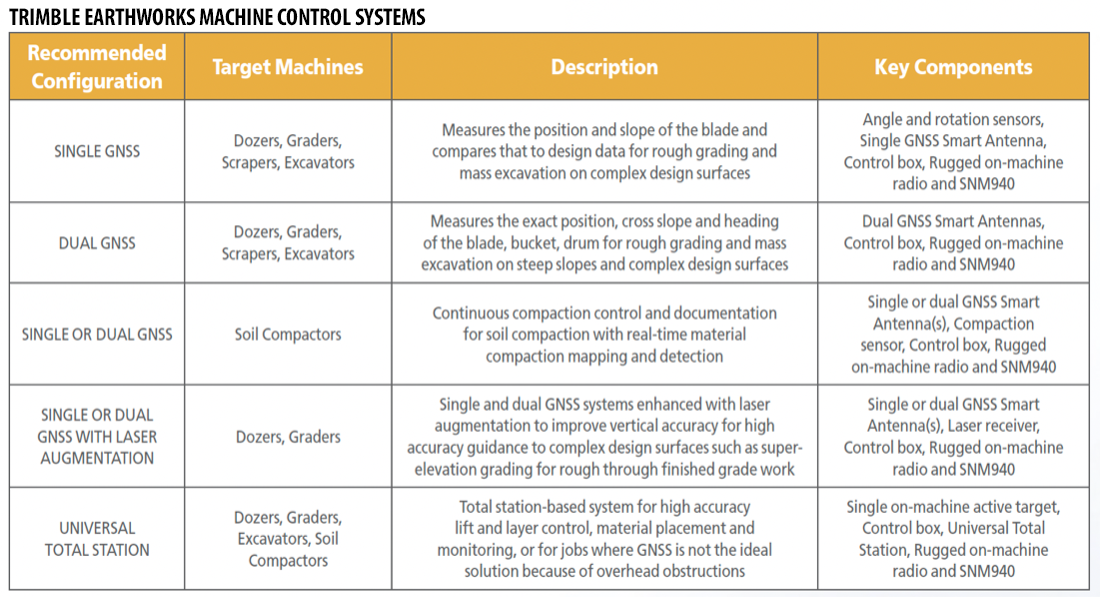

Traditional construction methods often rely on manual machine control, leading to inconsistencies and potential errors. Trimble provides advanced machine control systems that seamlessly integrate across your entire fleet — from bulldozers, excavators, scrapers, graders, compactors, pavers and more. With the use of GPS sensors, and laser-guided systems, these systems automate repetitive tasks and streamline construction workflows by eliminating guesswork and the need for manual adjustments. Operators can rely on automated controls to execute grading, excavation, and other tasks accurately, reducing human error and speeding up operations. Through advanced sensors and displays. Operators can monitor various parameters, such as bucket precision, blade elevation and compaction levels in real-time. The immediate feedback allows operators to adjust on the fly, ensuring work is carried out precisely and efficiently. Trimble offers both 2D and 3D machine control systems that have been perfected with industry-leading technologies tailored to your machine and application.

3. Enhanced Fleet Management:

3. Enhanced Fleet Management:

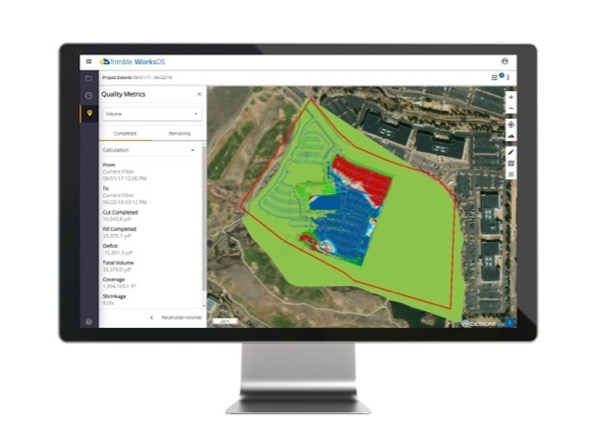

To maximize profitability, effective decision-making by the fleet and asset manager is crucial in terms of deployment, production health, and maintenance. However, we all know it is not physically possible for a manager to be present in the office and multiple job sites at once. Fortunately, with Trimble’s fleet and asset management solutions, real-time wireless reporting from the field can bridge this gap, enabling managers to make informed decisions as if they were virtually present in multiple locations at once. The SNM451 Connected Site Gateway will give you the location, run time, and utilization information you need to monitor your assets, wherever you are. The SNM941 Connected Site Gateway serves as a dedicated hotline, allowing you to send and receive vital information from the field. By efficiently managing your fleet, you can reduce downtime, lower maintenance costs, and increase overall project productivity. Some of the key features include:

-

- Real-Time Asset Tracking – By utilizing GPS and telematics technology, teams can track their assets with precision, offering real-time visibility into the location and status of their equipment. This enables companies to optimize their fleet, make informed decisions about equipment allocation, and reduce idle time.

- Maintenance and Diagnostics – These solutions provide real-time monitoring of critical parameters such as engine hours, fuel consumption and equipment diagnostics. By receiving timely alerts and notifications, fleet managers can schedule preventive maintenance, address issues promptly, and reduce the risk of unexpected breakdowns.

- Fuel Management and Optimization – With real-time fuel monitoring and reporting, companies can accurately track fuel consumption across their fleet. This data helps identify inefficiencies, monitor fuel theft or unauthorized usage, and implement strategies for fuel optimization.

- Compliance and Safety – Trimble’s fleet management solutions also play a crucial role in ensuring compliance with regulatory standards and enhancing safety by providing tools for monitoring driver behavior, including speed, harsh braking, and unauthorized vehicle usage.

Unlock Time and Cost Savings with SITECH Midway & Trimble

With the construction industry trending to upwards of $15 trillion by the end of 2023, having the right construction technology for your business is more important than ever. As technology continues to advance, Trimble remains at the forefront, enabling construction companies to be able to future-proof their practices and stay ahead of the curve. The ability to adapt to evolving industry demands, integrate new tools and techniques seamlessly, and harness the power of data analytics positions businesses for long-term success.

There are several technology options out there that can be overwhelming, so let us help. Our experienced team at SITECH Midway can help you find the right solutions for your fleet and ultimately help your business achieve greater profitability. Simply fill out our online contact form or call us at 847-931-0095 to get started today.