Paving Control for Asphalt Compactors

Eliminate the guesswork, roll a more efficient pattern, increase productivity and save fuel. The surface will speak for itself.

Features and Benefits

Trimble paving control systems help you roll a more uniform surface and increase your efficiency.

A Full-Color Graphical Display

- View compaction progress, pass counts and mat temperature information on an easy-to-use color display

Flexibility to Fit Your Needs

- Monitor pass counts only or pass counts plus temperature

- Add temperature sensors for precision accuracy

- Wirelessly transfer Intelligent Compaction data from the machine to the office with the Trimble SNM941 Connected Site Gateway

- Collect compatible data files that are ready to import into a Veta intelligent construction project

Reliability of the Trimble Paving Workflow

- Use one workflow from the initial design model to the last pass of the compactor

- Leverage on-machine components for milling, asphalt paving and compaction

- Monitor and analyze compaction efficiency from the office

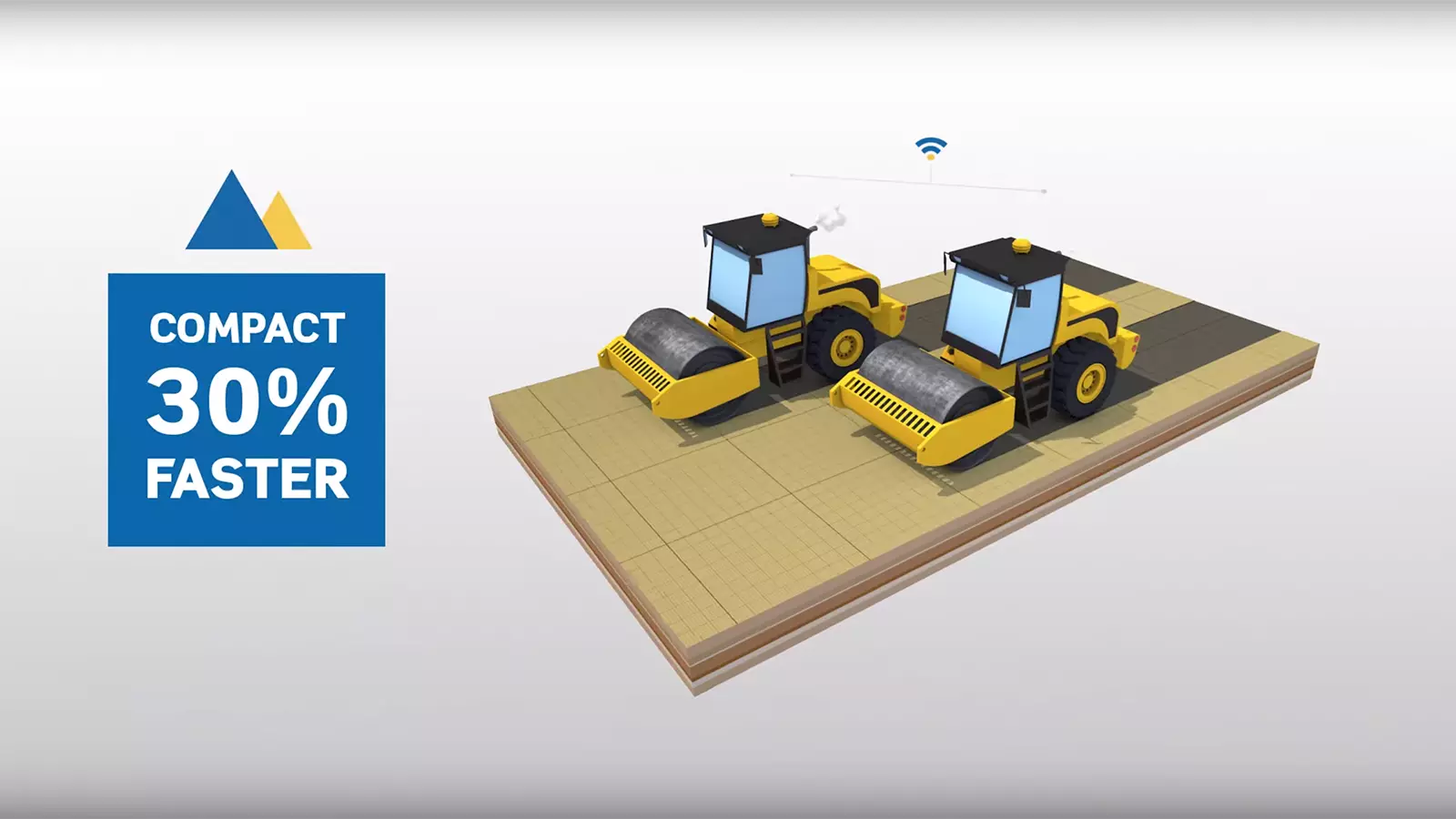

Trimble Roadworks Paving Control Platform for Asphalt Compactors

The next generation 3D paving control system designed to help operators of all skill levels improve the speed, accuracy and ease of asphalt compaction.

Software and Hardware Features

- Android-based software with the same familiar user interface as existing Roadworks applications

- Intuitive, easy to learn and configurable for a variety of workflow views: real-time temperature mapping, compaction progress, pass counts and optional display and recording of the compacted asphalt stiffness

- Powerful and rugged touch-screen displays designed for the field

Intelligent Compaction

- Compact surface material to the desired compaction stiffness target and monitor site volumes simultaneously, in real time

- Ensure optimal compaction per the target temperature range, reducing rework and material waste with real-time temperature map monitoring

- Achieve increased durability, stability and load-bearing capacity

- Support a variety of jobsite needs and specifications

Monitoring and Analysis

- Supervisors and quality managers can monitor compaction activities to track and report progress

- Real-time compaction data to improve layer management

- Monitor pass counts and compaction measurement values (CMV) over the entire area

- Improve testing success, reduce rework, operator hours and lower ongoing machine maintenance costs

- Reduce over-compaction to optimize fuel use and machine time

- Better understand work previously completed versus work completed that day

Connected Construction

- Reduce waste and overruns with efficient communication and data transfer with Trimble WorksManager Software—mobile-friendly application that easily manages data and technology assets across jobsites

- With the SNM941, wirelessly transfer 3D designs from the office to the machine

- Productivity data collected from the machine can automatically sync back to the office with Trimble WorksOS Software

- Office-only licenses offer extended functionality

Meet Our Customers

Learn how customers around the globe are using Trimble technology to be more efficient and profitable.

pp_s_add_config

pp_literature

pp_s_documentation

pp_s_contact